Order Roll Labels

QUESTIONS BEFORE YOU ORDER? GREAT–WE HAVE ANSWERS FOR YOU.

These are the most common questions our customers ask when choosing roll labels.

What sizes of roll labels does Hickman offer?

Roll label sizes vary depending on printer model, application, and material. Hickman offers roll labels in a wide range of shapes, including:

- Squares and rectangles (with square or rounded corners)

- Circles and ovals

- Continuous roll labels

- Custom die-cut shapes

Our team helps match label size and format to your printer specifications and application requirements to ensure proper feeding, print quality, and performance.

What materials are available on rolls?

Hickman offers roll labels in a variety of materials to suit different environments and use cases, including:

- Paper stocks for dry, indoor applications

- Film materials such as BOPP for moisture resistance and durability

- Clear films for a “no-label look”

- Specialty materials designed for demanding conditions

Material selection depends on factors like moisture exposure, handling, print method, and desired durability. Our specialists can help determine the best option for your application.

What surface types work best with roll labels?

Roll labels can be applied to many surface types, including glass, plastic, metal, and cardboard. Performance depends on surface characteristics such as:

- Smooth vs. textured finishes

- Flat vs. curved containers

- Clean vs. treated or coated surfaces

Choosing the right material and adhesive combination ensures proper adhesion and long-term performance on your specific surface.

How do I choose adhesive for roll labels?

Adhesive choice depends on how and where the label will be used. Common options include:

- Permanent adhesives for long-term labeling

- Removable adhesives for short-term or promotional use

- Specialty adhesives for cold, damp, or challenging environments

Factors like temperature, surface energy, and label lifespan all influence adhesive performance. Hickman’s team can help guide adhesive selection based on real-world conditions.

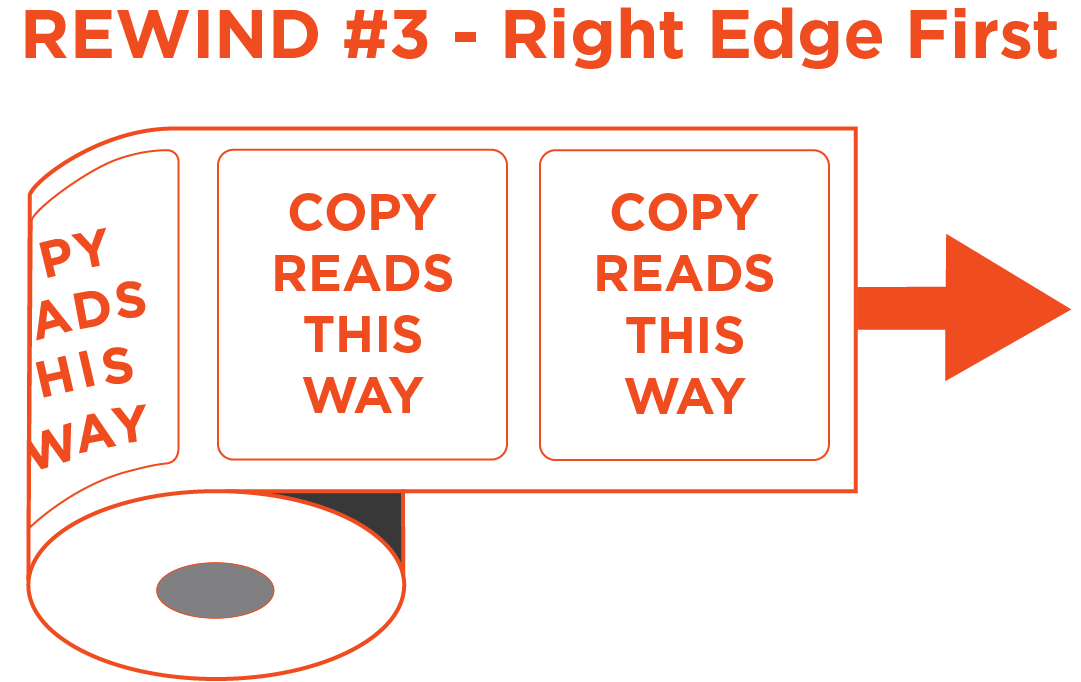

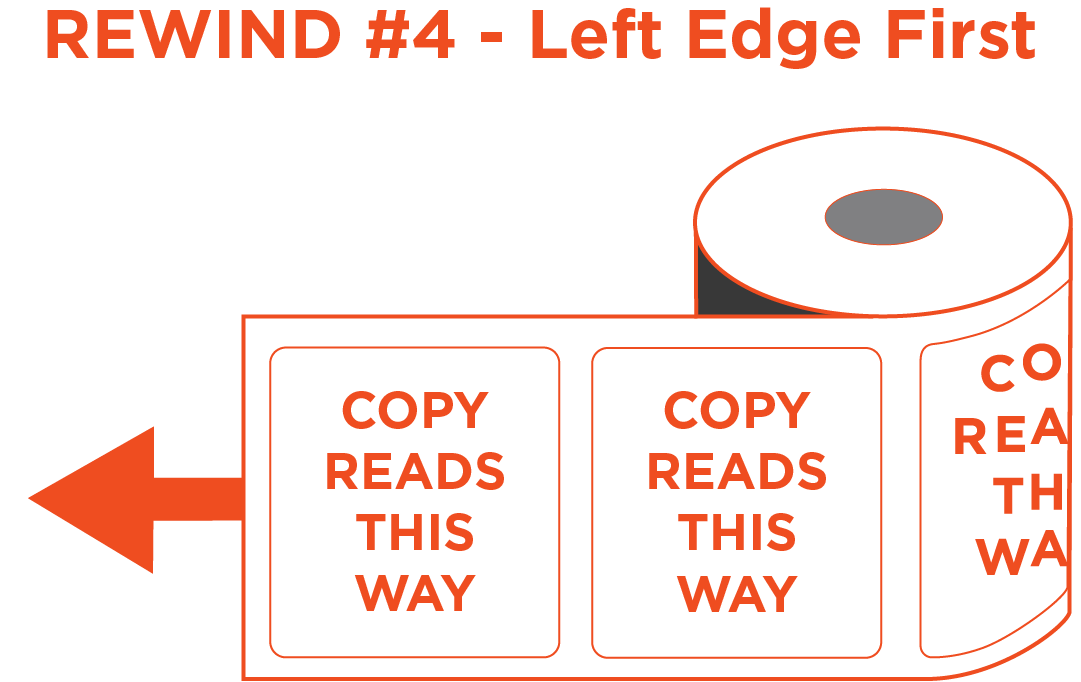

What is unwind direction and why does it matter?

Unwind direction refers to how labels are oriented as they come off the roll during printing or application. The correct unwind direction ensures:

- Proper feeding through printers or applicators

- Correct label orientation on the product

- Smooth, efficient application without jams or misalignment

Selecting the correct unwind direction is essential for compatibility with your equipment and workflow.

Can I print my own labels in-house on these roll labels?

Yes. Hickman roll labels are compatible with a wide range of inkjet, laser, and thermal printers. Printer compatibility depends on factors such as:

- Label material and coating

- Roll dimensions and core size

- Unwind direction and printer configuration

Our team helps ensure roll labels are properly matched to your printer to avoid feeding issues, smudging, or print quality problems.